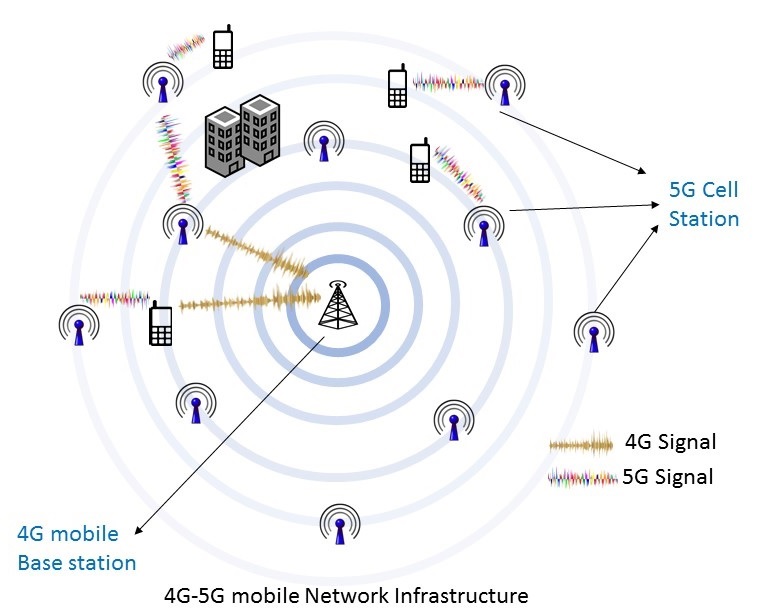

The arrival of 5G New Radio (NR) networks has improved mobile telephony service conditions. These improvements have made it possible to enhance other uses of these networks, such as localization. The higher bandwidths and directivity of 5G communications allow measurements taken from base stations to be more accurate, resulting in better position estimates than in previous generations of cellular networks. This makes localization applications based on cellular networks gain relevance. In addition, they are more efficient in terms of energy consumption, which is an advantage over GNSS systems.

The objective of this Graduate Thesis is to analyze and implement a localization algorithm based on 5G networks. This algorithm works outdoors and calculates the position locally, so the equipment to be located uses the measurements received from the base stations without interacting with any other element of the network. Certain accuracy and execution time requirements have been established.

To accomplish the objective, a study of the outdoor localization methods based on cellular networks has been carried out in order to select the most accurate one among those reviewed.

Subsequently, the corresponding algorithm has been implemented in a microcontroller, to finally test its performance in different simulated scenarios.

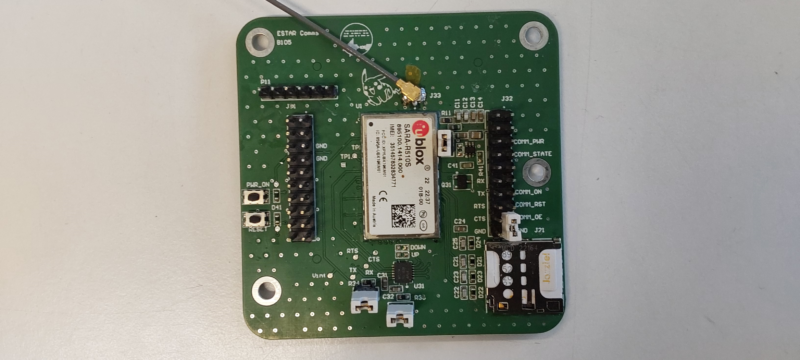

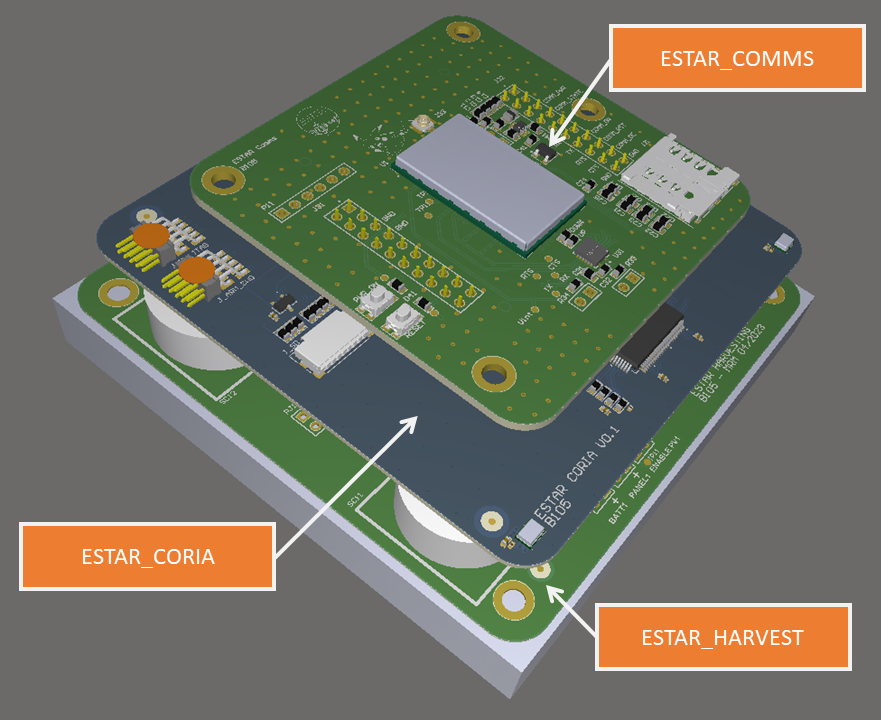

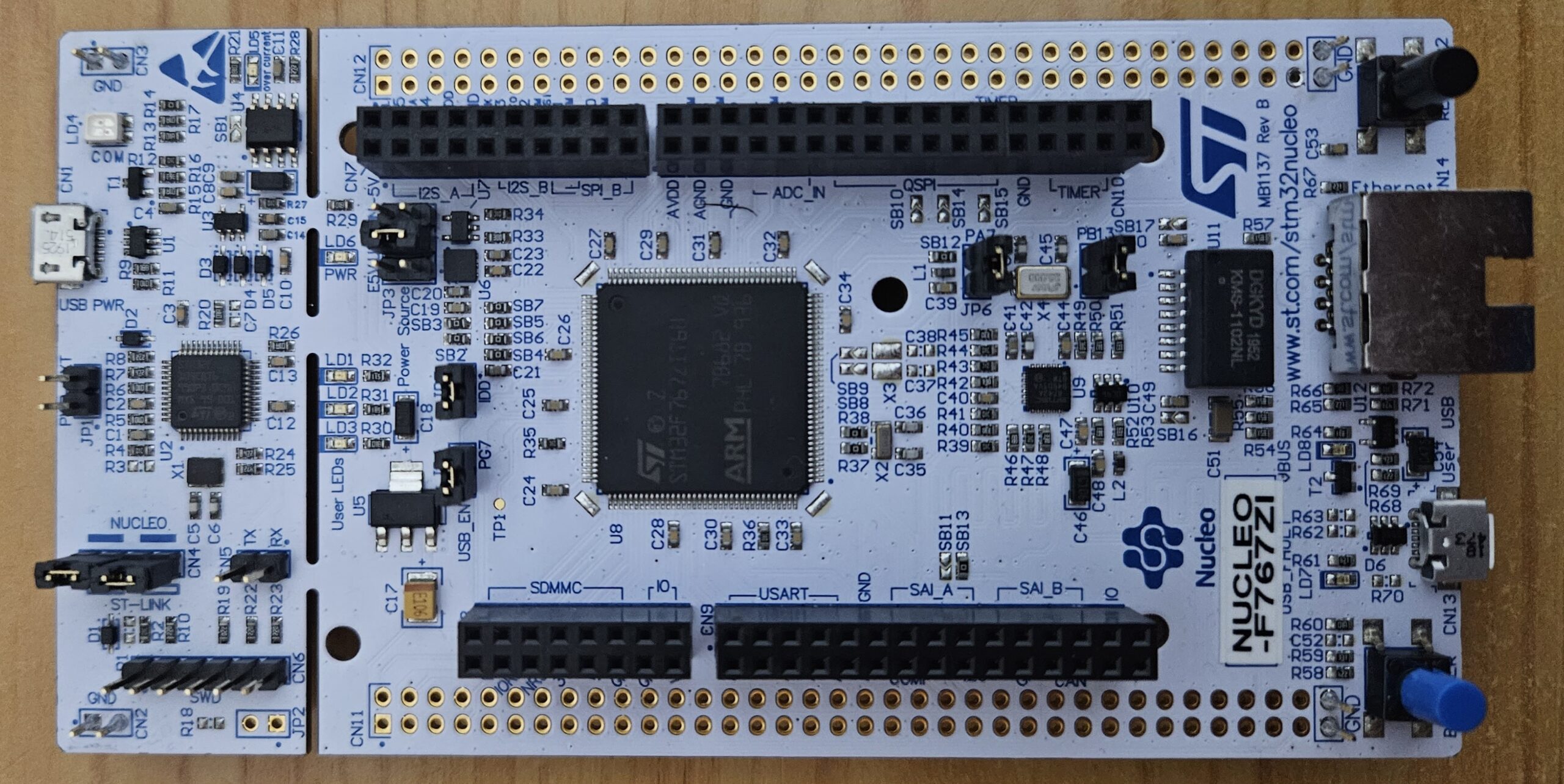

At the hardware level, the STM32 NUCLEO-F767ZI microcontroller has been used.

At the software level, the STM32CubeIDE development environment and C programming language have been used. Since it has not been possible to experimentally obtain the measurements required for the algorithm to work, some Matlab scripts have been created to simulate both these measurements and the test scenarios.

After testing its performance in different scenarios, it can be concluded that the implemented algorithm meets the objectives set, both in terms of accuracy and time, and that it could therefore be interesting to carry out tests in a real scenario.